Page 10 - ESDMAN CO., LTD.

P. 10

Ionizing Air Bar

001-5819

24VDC

Input Power

Setting Method

Remote control, monitoring software

Output Ion High Voltage

<15uA, the current is limited to avoid the risk of electric shock

Output Current 0j20KVDC±10% The ratio of positive and negative high voltage output can be adjusted separately

Interface

Room Ionization System Each Ionizing air bar has interfac at both ends

The precise timing of the adjustment level is 0-15 seconds @ The accuracy level of time adjustment

॥ᇅ

is about 0.1 seconds

Operation Mode Pulse DC, normal DC, standby

Tungsten alloy, titanium alloy, single crystal silicon, emitter needle is replaceable, useful life is

Material of Emitter Needle

related to the environment, about 2-3 years

Alarm Indication LED (Red): It will light up when the high voltage of the Ionizing air bar is abnormal

Normally we recommend to make calibration every 3-12 months (depends on environmental

Maintance

conditions)

Ozone < 0.005ppm

Installation Method Equipped with a fixed bracket

Application Environment Temperature: 18°C-27°CHumidity: 40-60% (non-condensing)

Dimension W3.7cmxH5.9cmxL57/72/90/113/140/164/192/215cm

Weight 605g(72cm)

Warranty One year

Certificate

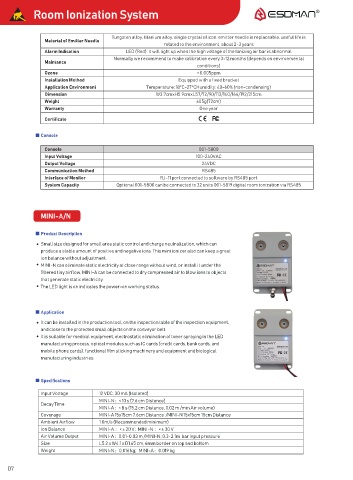

Console

Console 001-5800

Input Voltage 100-240VAC

Output Voltage 24VDC

Communication Method RS485

Interface of Monitor RJ-11 port connected to software by RS485 port

System Capacity Optional 001-5800 can be connected to 32 units 001-5819 digital room ionization via RS485

MINI-A/N

Product Description

Small size designed for small area static control and charge neutralization, which can

produce a stable amount of positive and negative ions. This mini ionizer also can keep a great

ion balance without adjustment.

MINI-N can eliminate static electricity at close range without wind, or install it under the

filtered tiny airflow, MINI-A can be connected to dry compressed air to blow ions to objects

that generate static electricity.

The LED light is on indicates the power-on working status.

Application

It can be installed in the production tool, on the inspection table of the inspection equipment,

and close to the protected small objects on the conveyor belt.

It is suitable for medical equipment, electrostatic elimination of toner spraying in the LED

manufacturing process, optical modules such as IC cards (credit cards, bank cards, and

mobile phone cards), functional film sticking machinery and equipment and biological

manufacturing industries.

Specifications

Input Voltage 12 VDC, 30 mA (Isolated)

MINI-Nğ< 10 s (7.6 cm Distance)

Decay Time

MINI-Ağ< 8 s (15.2 cm Distance, 0.02 m /min Air volume)

Coverage MINI-A 15x15cm 7.6cm Distance /MINI-N 15x15cm 15cm Distance

Ambient Airflow 1.0m/s (Recommended minimum)

Ion Balance MINI-A ğ< ± 20 V ; MINI-N ğ< ± 30 V

Air Volume Output MINI-Ağ0.01-0.03 m /MINI-N: 0.3-2.1m bar input pressure

Size L5.2 x W4.1 x D1.65 cm, 6mm border on top and bottom

Weight MINI-Nğ0.016 kg; MINI-Ağ0.019 kg

07